In the agricultural and veterinary fields, the quality and design of injection needles play a pivotal role in ensuring effective and ethical handling of animals. A good injection needle is one that not only serves its intended function with precision but also minimizes discomfort for the animal and reduces the risk of injury to both the animal and the handler.

This article delves into the key parameters of needle manufacturing, packaging, and the overarching function and risks associated with using injection needles. Additionally, it outlines what criteria one should consider when choosing a needle for veterinary and agricultural applications.

Key take-aways

- Opt for high-quality stainless-steel needles (304 or 316) due to their durability, corrosion resistance, and sharpness

- Choose appropriate length, diameter, and bevel design based on injection type, animal size, and skin type for effective and comfortable injections

- Ensure needles are securely packaged to prevent contamination. Packaging should be easy to handle for quick and efficient use.

- Handle needles carefully to avoid breakage, bending, and infection. Adhering to manufacturer recommendations and undergoing regular training are essential for user safety and animal welfare.

Manufacturing and materials used: the case for stainless steel

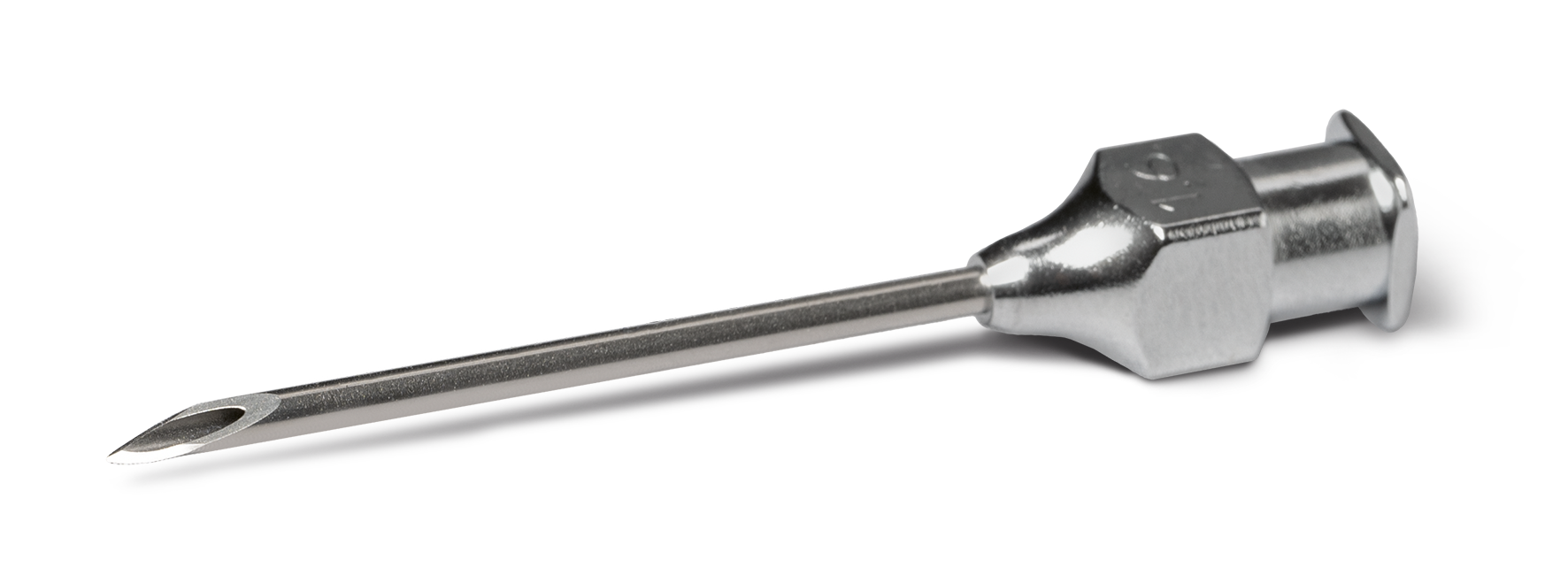

Needle manufacturing processes begins with a stainless-steel strip. This strip is rolled into a tube shape and seams welded into a cylinder using a laser. The cylinder is then passed several times through a die that reduces its outer and inner surfaces to obtain the desired diameter. Next, the steel tubing is cut to its final length, and bevelled. Finally, the hub is attached to the needle base.

Stainless steel 304 or 316 is the golden standard in needle production due to its corrosion resistance, durability, and biocompatibility. Stainless steel ensures that the needle remains sharp and does not corrode or rust, which could lead to contamination of the medication or vaccine being administered. The material's strength also supports a variety of wall thicknesses and needle lengths, accommodating different types of injections, from subcutaneous to intramuscular.

Wall thickness and robustness

The robustness of the needle, determined by its wall thickness and construction, is crucial for withstanding the rigors of agricultural applications. Thicker walls provide more resistance, reducing the risk of bending or breaking during an injection, which is especially important when dealing with larger animals or tough skin.

"Based on user feedback, Socorex needles are known for their exceptional durability, lasting 10 to 30 times longer than competing products. The needle portfolio is broad, with custom dimensions available upon request. Moreover, Socorex offers practical accessories such as the AbacusTM shot counter allowing to monitor injection counts, ensuring timely needle replacement for optimal performance."

Bevel type and sharpness

The bevel of a needle refers to the angle at the tip that allows for skin penetration. Precision grinding techniques are employed to achieve the desired sharpness and geometry of the bevel. A good injection needle has a bevel that is sharp enough to penetrate skin with minimal resistance, reducing discomfort and tissue damage. The type of bevel—such as short, long, or trocar—should be selected based on the injection technique and the animal's skin type.

Packaging of needles

Packaging is not merely about convenience; it is also about safety and integrity of injection needles until the point of use. It reduces the risk of contamination, ensuring that each injection is as safe and clean as possible. The packaging should also be easy to open to facilitate quick and efficient handling during veterinary procedures.

"In Socorex packaging, the needles are arranged with an offset so that when you slide the lid, only one needle falls out. Needle hubs are clearly visible, with the diameter engraved in millimetres and Gauge size. Conveniently, the lid can be slid open singlehandedly."

Function of an injection needle and associated risks

Injection needles work in concert with injection syringes and serve as conduits for delivering medications, vaccines, or treatments into the body of an animal efficiently and safely. However, using needles comes with risks, including needle breakage, bending, and the potential for causing injection site infections or abscesses if the needle is not clean or is changed too infrequently. The consequences are far reaching and impact animal welfare (inflicting unnecessary pain) and subsequently devalue the primal cuts or whole carcase. There's also the risk of needle-stick injuries to the handler, emphasizing the need for careful handling and disposal.

"Some companies propose solutions to minimize the risk of needle-stick injuries. One interesting solution from Socorex, extremely useful especially in the fish industry, is the FishGuideTM– a copper loop that facilitates accurate injection of fish, while protecting operator's hand from accidental self-injection."

Preparing for your next vaccination campaign: what to consider

When selecting an injection needle for your next vaccination campaign, consider the following parameters:

- Length and diameter: Choose the length and diameter based on the type of injection (subcutaneous, intramuscular, or intravenous), the size and species of the animal and the viscosity of the liquid being injected. Small needle diameter may restrict the flow of medication, requiring more force for the injection and potentially causing more stress to the animal. Larger animals and deeper tissues require longer, thicker needles.

- Material quality: Opt for high-quality stainless steel to ensure durability, sharpness, and corrosion resistance.

- Bevel design: Select the bevel design that best suits the injection technique and minimizes animal discomfort.

- Robustness vs. flexibility: Balance the need for a robust needle that won’t easily bend or break against the need for a needle that can be used with minimal force.

- Packaging: Favor ease of use.

Apart from purely technical considerations, the right needle requires a reliable syringe, effective vaccine and trained staff. Mind that vaccine manufacturers usually provide very clear recommendations on the adequate dose and needle sizes for their products – make sure you check out this information beforehand. Lastly, let’s not forget about the role of regular trainings and investing in upgrading the knowledge and practical skills of the vaccination crew.

"As a Socorex client, you receive comprehensive support. Our expert team offers a wide range of customizable workshops, both online and onsite, ensuring you're fully equipped to use our products with confidence. Benefit from personalized training and guidance from specialists who possess in-depth knowledge of syringes and needles, ready to assist you at every step."

Conclusions

A good syringe deserves a good injection needle (just as a sports car requires reliable tires). It is more than just a tool—it's a testament to precision engineering and a commitment to animal welfare. By prioritizing key technical parameters and choosing a reputable brand, farmers and injection technicians can ensure safe and effective delivery of treatments to the livestock. With the right needle in hand, they can administer injections with confidence, knowing that they are promoting the well-being and success of their agricultural operations.

Remember that: Reliable tools (needles + syringes) + vaccine + trained staff = successful vaccination campaign

References

- Haurine T. Utilisation des aiguilles dans la profession vétérinaire : un état des lieux et une réflexion au niveau national. Médecine vétérinaire et santé animale 2023 ⟨dumas-04260687⟩

- Using medicines responsibly. As little as possible, but as much as necessary. Agriculture and Horticulture Development Board (AHDB) 2020, version 70032 0923, available at https://ahdb.org.uk/knowledge-library/using-medicines-for-better-returns (accessed on 07.02.2024)

- Rethorst DN. Animal Health Equipment Management. Vet Clin North Am Food Anim Pract. 2015 Jul;31(2):259-67. doi: 10.1016/j.cvfa.2015.03.009. PMID: 26139191; PMCID: PMC7135019

- Antibiotic stewardship for beef producers. Beef Quality Assurance (BQA) 2020, available at https://www.bqa.org/resources/updated-antibiotic-guidelines (accessed on 07.02.2024)

- Faè G. Micro-dose vaccines: Why less is more. Hatchery Feed & Management Vol 10 Issue 2, 2022